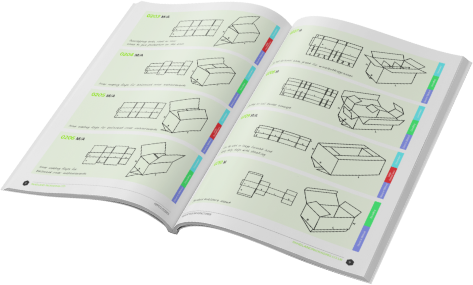

When you need a Standard Box fast, come to Sandland Packaging. We are able to supply any design in the 02 range and these boxes can be supplied single or double walled depending on the product being packaged and how robust the boxes need to be. They are fully overlapping and available in any quantity. Our Standard boxes are fully recyclable and are certified CarbonNeutral.

Include your branding

Where you want your brand to standout, we can print the boxes to match your corporate colours. This adds the wow factor making delivery of your product feel even more special and exciting.

Items which are heavy and difficult to handle need packaging of the highest quality to keep it safe and well protected. We design and manufacture Large Format Cases to perfectly fit your valuable products, ensuring they reach their destination in superb condition. If these need additional security, we produce Transit Packaging – designed entirely around ensuring successful and stress-free transportation.

When products are an unusual or complex size or shape, we’re here to help. Our experts will use our trusted design process to create perfect fit packaging specifically for your product requirements to ensure it is delivered exactly as specified in perfect condition.

Stitching is a much-needed requirement for any corrugated packaging needing a more robust seal, helping to avoid splitting on the seam. This is particularly true for Large Format Cases and Pallet Cases but also for other boxes which need additional reinforcement. To cater for all bespoke box requirements, we have multiple machines with stitching capabilities.

One of our recent new investments, Midas MD Ultra Fully Automatic Stitcher/Gluer, has really improved our capability and turnaround stitching at 90 metres per minute on volume requests. Or our two piece Godswill stitcher allowing for large pallet cases to be combined for much bigger cases.

If you’re not sure whether you need stitched boxes, we’re here to help. Let our friendly team of experts look at your requirements, design a prototype and provide a sample. You can rest assured we can provide perfect fit packaging.

Usually consisting of many thousands of multiple items, we are skilled at creating packaging that holds the optimum number of items. This will take into account how many can be safely stored, stacked and packed for transportation. It will also make sure the maximum number of items are packed together to avoid any wasted space while ensuring they are packed efficiently without risk of breakage or damage.

We’ve designed and manufactured food and drink packaging for a large number of items so we know we can provide the right packaging for you. Our team of experts will look at your requirements, design a prototype and provide a sample. You can rest assured we can provide perfect fit packaging.

For many companies off-the-shelf packaging is not sufficient. Your whole operation is centred around producing the highest quality product which then requires a bespoke packaging solution to transport it to its end destination in perfect condition. That’s where we come in. We’re experts at designing the perfect bespoke packaging solution to protect your product.

We’ve designed and manufactured every size and shape of packaging from the very small component to the very large and secure pallet case so we know we can provide the right packaging for you. Our team of experts will look at your requirements, design a prototype and provide a sample. You can rest assured we can provide perfect fit packaging.

Electronic packaging often needs to secure multiple items and can be many sizes and shapes. We are skilled at creating packaging such as Divider Sets that holds the optimum number of items. This will take into account how many can be safely stored, stacked and packed for transportation. It will also make sure the maximum number of items are packed together to avoid any wasted space while ensuring they are packed efficiently.

We’ve designed and manufactured electronic packaging for a large number of items so we know we can provide the right packaging for you. Our team of experts will look at your requirements, design a prototype and provide a sample. You can rest assured we can provide perfect fit packaging.

This guide has been produced to help our customers and includes all FEFCO designs that can be produced by Sandland Packaging.