Do you need to know more about corrugated packaging and how it can provide the best packaging options for your company’s products? You’re in the right place. We’re experts in industrial packaging and can help guide you through the options from the basics of corrugated right through to how to make the right choice for your packaging needs.

Corrugated cardboard is comprised of card and paper glued together to make a strong material useful for packaging. It consists of layers: usually an inner liner, an outer liner, and a fluted layer in between.

The Inner and outer liners can be made up of a combination of recycled and kraft liner depending on the requirements and the outer liner can be printed for product or delivery instruction or branding purposes. The fluted layer adds rigidity to the cardboard and comes in a variety of thicknesses dependent on the weight and fragility of the products being stored or transported.

One of the key questions with regards to using corrugated cardboard for packaging is how thick the corrugated cardboard should be for the packaging requirement. Too thick and more material is used than necessary which wastes money and resource; too thin and the boxes could break or burst and the contents damaged. It’s vital to get this right. Let’s look at the individual elements:

Liners – The inner and outer liners can be made from different material grades to provide different levels of protection and puncture resistance. Material grades are often expressed in gsm or grammage per square metre: essentially how much a square metre of the material weighs. While this is not specifically a measure of thickness, as paper can be subject to a mechanical process which make the paper thinner (known as calendering), it is nevertheless a good indicator of strength.

Examples of available liner grades are: 125, 150, 200 and 300gsm.

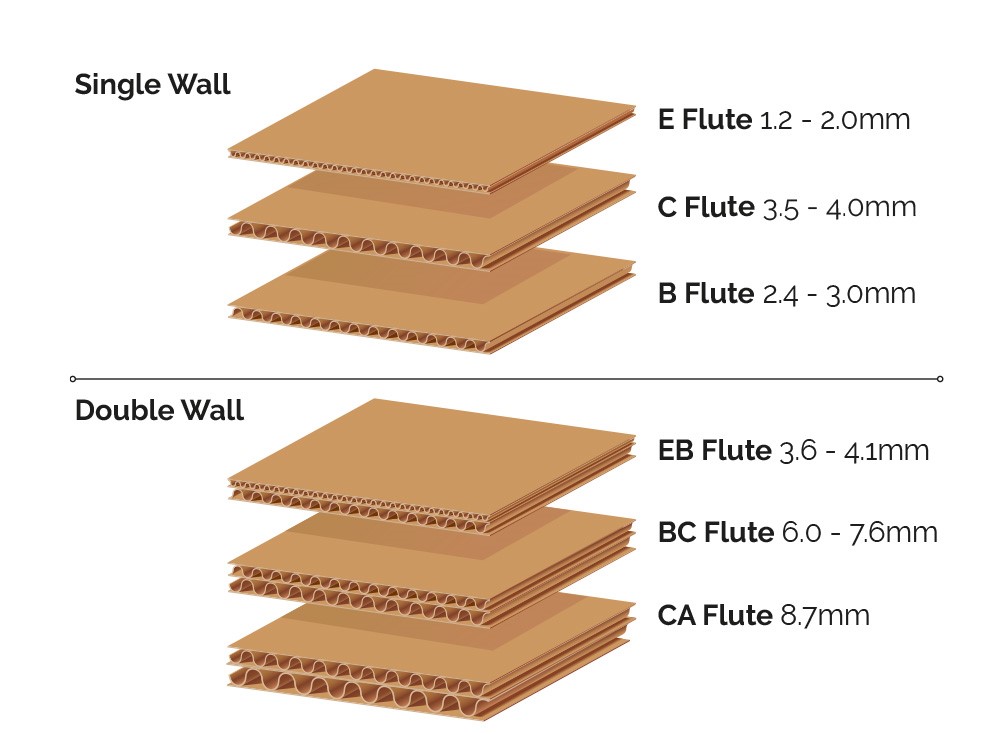

Fluting – Fluting can be very thin or very thick depending on the needs of the packaging: a thin grade like E Flute is good for printing on; thicker B Flute is more used in transit packaging. Using one of these on their own is known as Single Wall. They can also be manufactured together to create a Double Wall product which means harnessing the best of both options – allowing for a smoother printing surface together with robust protection. A Triple Walled product – called Tri-Wall – is available and is the brand name of the manufacturer.

Good question! It’s worth checking out a bespoke packaging option for many requirements, including packaging where you need to safely pack multiple components, where the items are large or heavy and for items that are an unusual shape.

Bespoke packaging really works for any item that doesn’t fit into a standard box. Using packaging that is a perfect fit protects your products, minimises space in storage and transport and, most importantly, reduces damage in transit.

By its nature, bespoke packaging varies depending on the product. It includes the type, size and strength of the box and the fitments used within the box, like the ones shown below:

Don’t forget, the friendly team at Sandland Packaging are always on hand to help you make the right choice.

All packaging manufactured by Sandland Packaging is FULLY CarbonNeutral and includes reporting emissions within Scopes 1, 2 and 3. This helps your business in three ways: Your organisation is supported on its journey to NetZero; your organisation can report packaging as zero emissions for GHG reporting and your customers can see your commitment to sustainable practices.

Our full Carbon Neutral status is part of our ongoing journey to becoming Carbon NetZero by 2040. In addition to this we have achieved Forest Stewardship Council® (FSC®) certification and plant one tree in the UK for every five orders manufactured. You can rest assured sustainability is at the heart of our business.

Where you need to make your packaging more sustainable – talk to us. We’re experts in designing effective, affordable alternatives to plastic, polystyrene or foam packaging or fitments. See how we helped an electronic manufacturer replace foam layer pads in their packaging.

Cardboard itself is a sustainable resource made from recycled materials – FEFCO confirms, corrugated packaging has 89% recycled content on average. It is also easy to recycle after use – according to Statista In 2021, 5.4 million metric tons of paper and cardboard packaging was created by households in the United Kingdom. Of this total, 3.8 million metric tons was recovered, giving a recycling rate of roughly 71 percent.

Let our experienced team take you through an audit of your requirements to make sure you get the best fit packaging for your products. This will include details of the product, to make sure the packaging provides the perfect support and cushioning, and the manufacturing process, to ensure the packaging is quick and easy to assemble. You will want to consider whether your production team need to seal the boxes or if an integral closing mechanism would be more efficient. You might also need the boxes to be printed for ease of instruction or branding.

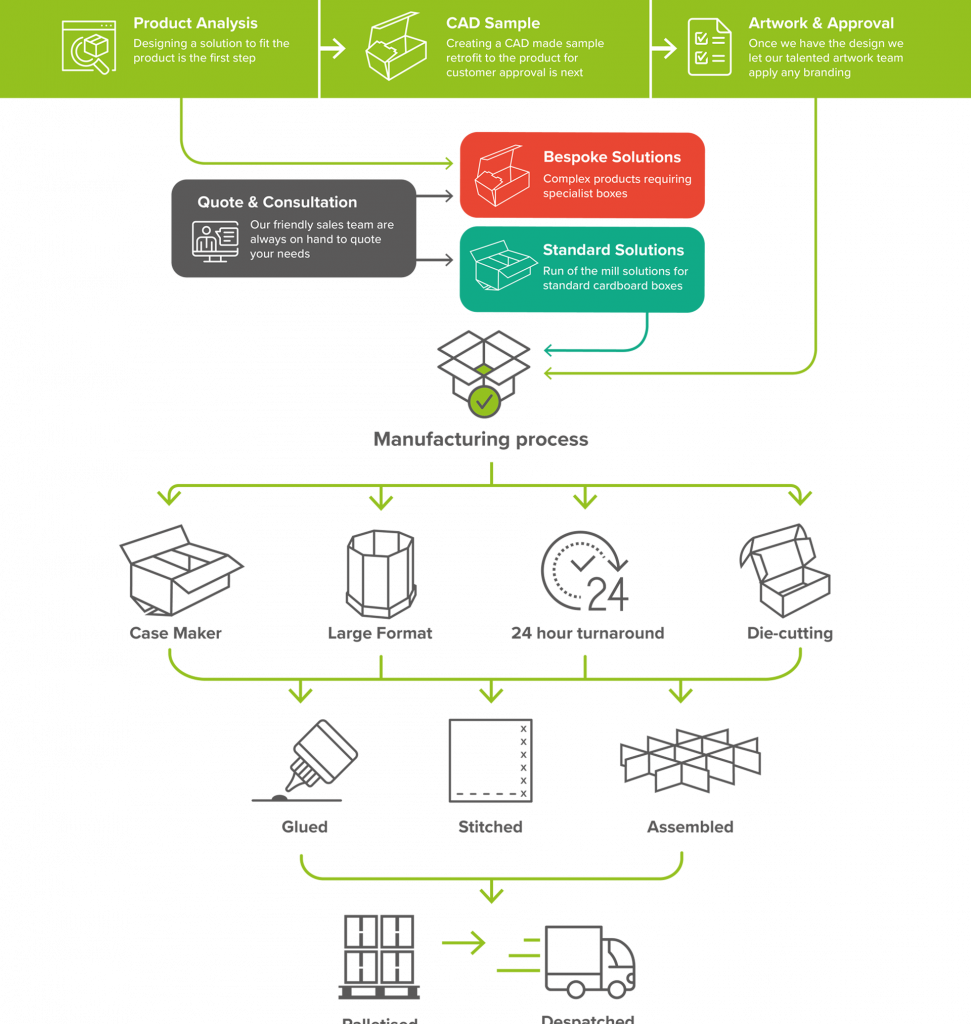

Our team will use the Design Process to take you through the options:

Printing on your packaging may help it to stand out or provide useful instructions to customers. At Sandland Packaging, we can print in two colours flexo to give you the high-quality results you need. Printing on your boxes may help your packaging to:

Make an impact – Create a striking design no one can miss, which is very useful for important constructions like the Collections4Clothes Hex-abin.

Impress your customers – Make receiving a package truly special by including your branding and accreditations like this drinks company.

Give clear instructions – Industrial packaging may need handling instructions like ‘fragile’ or include information about what’s inside if the product is glass or if it’s flammable. Some product packaging requires legal messages and marks for regulatory purposes.

The three key benefits to using corrugated are:

Before deciding on your packaging design, we’ll help you conduct thorough testing for strength, durability, and ability to withstand storage and transport conditions. We’ll provide samples for you to test to make sure your design is perfect for your needs.

Our team are experts in packaging design and manufacture. For more help and advice, don’t hesitate to speak to the Sandland Packaging team.

More news from Sandland Packaging